FRAC PACKAGE - 2 FLEETS, OVER 1900+ ASSETS

SOLD / NO LONGER AVAILABLE

Email for more infoCost over $63-Million New

Make an offer, motivated seller

Like New Condition, Low Hours

Located in Europe

Shipping & Custom Brokers available

Call to Inspect and Buy Today!!!

Call NOW! (800) 952-1973

Listing Details

|

Asset |

Qty |

| Core Fleet Equipment | |

| FT-2251 Trailer | 30 |

| Data van | 2 |

| CHEMICAL ADDITIVE | 1 |

| MT132 Blender | 3 |

| Trailer Mounted Hydr | 2 |

| LAB VAN | 1 |

| Fracpro License | 4 |

| MANIFOLD TRAILER | 2 |

| SAND KING 3000 | 2 |

| Ancilliary Equipment | |

| 4" Iron and Materials | |

| CROSSOVER ASSY 4" | 97 |

| CHECK VALVE CLAPPE4" | 8 |

| 4" CROSSOVER | 10 |

| BULL PLUG 4" | 20 |

| LATERAL ASSY 4" | 12 |

| PLUG VALVE 4" | 6 |

| SWIVEL ASSY 4" | 58 |

| TEE ASSY 4" | 20 |

| 3" Iron and Materials | |

| BALL INJECTOR ASSY3" | 2 |

| CHCEK VALVE CLAPP 3" | 10 |

| 3"FIG1502 PLUG VALVE | 2 |

| BULL PLUG ASSY 3" | 34 |

| 3" FIG1502 ADJ CHOKE | 2 |

| 3" FIG1502 ADJ CHOKE | 2 |

| CROSSOVER ASSY 3" | 2 |

| CHECK VALVE CLAPPE3" | 4 |

| Crossover Assy3" | 2 |

| 3" FIG1502 THRD x3" | 2 |

| 3" FIG1502 THRD x2" | 2 |

| LATERAL ASSY 3" | 12 |

| PIPING ASSY 3" | 80 |

| PLUG VALVE 3" | 8 |

| PUP JOINT ASSY 3" | 75 |

| PUP JOINT ASSY3" | 15 |

| RELLEF VALVE 3" | 4 |

| SWIVEL ASSY 3" | 178 |

| TEE ASSY 3" | 31 |

| Tee Assy 3" Fig 1502 | 5 |

| Tee Assy 3" fig1502 | 5 |

| WYE ASSY 3" | 4 |

| Swivel Joint Assy 3" | 5 |

| 2" Iron and Materials | |

| CROSSOVER ASSY 2" | 4 |

| FEMALE BULL PLUG 2" | 3 |

| LATERAL 2" | 5 |

| LATERAL ASSY 2" | 5 |

| PLUG VALVE 1x2" | 12 |

| PLUG VALVE 2" | 22 |

| Relief Valve 2" | 4 |

| SWIVEL ASSY 2" | 24 |

| TEE ASSY 2" | 51 |

| Other Equipment | |

| DUAL BELT | 1 |

| ENGINE DRIVEN PUMP | 2 |

| CHUTE SAND | 1 |

| LOW PRESSURE MAIFOLD | 1 |

| MANIFOLD/PIPE SKID | 1 |

| SINGLE BELT | 1 |

| MikroMotion Coriolis | 5 |

| PROGRAMMABLE LOGIO | 2 |

| Spares for LAS | 11 |

| SEAT PULLER ASSY | 5 |

| Spare Fluid Ends (in Inventory) | |

| 4.5" | 12 |

| 5.5" | 7 |

| Support Vehicles | |

| Leased Tractors *** | 33 |

| Sandking 2000 and Sand Conveyer | 8 |

| Frac Tank and Associated PPE | |

| Other Leased Vehicles *** | 13 |

| Iron Trailer | |

| Crane | 1 |

| Owned Vehicles | 9 |

| Flowback Equipment | |

| Other | |

| Pipes & Connectors | |

| Buildings and Generators | |

| Furniture, IT, & Software, etc. | |

| Residual LAS PPE | |

***Optional to Continue Lease

Equipment Technical Data

The stimulation equipment was designed to provide the following services:

- High rate high pressure proppant fracturing (up to 130 BPM at 15,000 psi),

- Multi stage fracturing operations,

- Low rate proppant fracturing treatments,

- Frac packs,

- Gravel packs

- Acid fracturing treatments,

- Energized fluid fracturing treatments.

Well Stimulation Service Overview

Fracturing equipment currently available:

|

Equipment |

Quantity |

Date of manufacture |

Manufacturer |

Technical Details |

|

Fracturing Pump |

30 |

2011 |

Steward&Stevenson, Texas |

15K working pressure, 4.5’’ or 5.5’’plungers, 2000HHP |

|

Fracturing Blender |

3 |

2011 |

Steward&Stevenson, Texas |

130 BPM capable |

|

Hydration Unit |

2 |

2011 |

Steward&Stevenson, Texas |

120 BPM capable |

|

High Rate Manifold |

2 |

2011 |

C.A.T. Construction, Germany |

15K working pressure, 128 BPM capable |

|

Sand Mover E-type |

8 |

2011 |

Convey-All Industries, Canada |

80 mt proppant storage |

|

Sand Mover A-type |

2 |

2011 |

Convey-All Industries, Canada |

100 mt proppant storage |

|

Liquid Additive System |

1 |

2011 |

C.A.T. Construction, Germany |

Self-contained chemical storage and dosing |

|

Data Acquisition Center |

2 |

2011 |

Steward&Stevenson, Texas |

Self-powered via onboard generator |

FT-2251T Stewart & Stevenson High Pressure Pump - 4.5’’ Plunger

The Stewart & Stevenson High Pressure Pump - Model FT-2251T is a trailer-mounted fracturing unit capable of pumping inhibited acid and other proppant laden stimulation fluids in harsh oilfield environments.

Description

The FT-2251T is remotely operated from the U-DAC or alternatively a suitcase control box. This unit is capable of operating in an ambient temperature range of -40oC to +50oC. The deck engine is capable of delivering 2250 BHP to the engine flywheel at SAE conditions and the pump is capable of delivering 2000 HHP. There are a combined 30 units of the 4.5 and 5.5 Plunger Units available.

|

Tech Specs Dimensions |

• Length: 13,20 m |

|

Deck engine |

• Diesel’s Engine, MTU 12V4000 |

|

Cooling system |

• Remote horizontal cooler with vertical exhaust air system installed on the upper deck |

|

Hydraulic systems |

• 1 - Wet-kit: Supplies hydraulic starting system of deck engine, includes a hydraulic pump driven directly from the transmission in the tractor using power-take-off (PTO) |

|

Suction manifold |

• The 6’’ suction manifold terminates with two 4’’ Fig. 206 winged connections

|

|

Discharge manifold |

• The pump’s rear discharge port is connected to the discharge manifold via a 3’’ Fig. 1502 winged connection |

|||||||||||||||||||||||||||||||||||||||||||||||

|

Control devices |

• Electrical junction box |

|||||||||||||||||||||||||||||||||||||||||||||||

|

Winter equipment |

• Webasto heating system with heat exchanger for heating the fluid’s containers: |

|||||||||||||||||||||||||||||||||||||||||||||||

|

Pump system |

• SPM TWS-2250 triplex pump (autofrettaged fluid-end, high strength alloy steel fluid-end) |

|||||||||||||||||||||||||||||||||||||||||||||||

|

Transmission |

• Allison S9820 CEC3

|

FT-2251T Stewart & Stevenson High Pressure Pump - 5.5’’ Plunger

The Stewart & Stevenson High Pressure Pump - Model FT-2251T is a trailer-mounted fracturing unit capable of pumping inhibited acid and other proppant laden stimulation fluids in harsh oilfield environments.

Description

The FT-2251T is remotely operated from the U-DAC or alternatively a suitcase control box. This unit is capable of operating in an ambient temperature range of -40oC to +50oC. The deck engine is capable of delivering 2250 BHP to the engine flywheel at SAE conditions and the pump is capable of delivering 2000 HHP. There are a combined 30 units of the 4.5 and 5.5 Plunger Units available.

|

Tech Specs Dimensions |

• Length: 13,20 m |

|

Deck engine |

• Diesel’s Engine, MTU 12V4000 |

|

Cooling system |

• Remote horizontal cooler with vertical exhaust air system installed on the upper deck |

|

Hydraulic systems |

• 1 - Wet-kit: Supplies hydraulic starting system of deck engine, includes a hydraulic pump driven directly from the transmission in the tractor using power-take-off (PTO) |

|

Suction manifold |

• The 6’’ suction manifold terminates with two 4’’ Fig. 206 winged connection

|

|

Discharge manifold |

• The pump’s rear discharge port is connected to the discharge manifold via a 3’’ Fig. 1502 winged connection |

||||||||||||||||||||||||||||||||||||||||||||||

|

Control devices |

• Electrical junction box |

||||||||||||||||||||||||||||||||||||||||||||||

|

Winter equipment |

• Webasto heating system with heat exchanger for heating the fluid’s containers: |

||||||||||||||||||||||||||||||||||||||||||||||

|

Pump system |

• SPM TWS-2250 triplex pump (autofrettaged fluid-end, high strength alloy steel fluid-end) |

||||||||||||||||||||||||||||||||||||||||||||||

|

Transmission |

• Allison S9820 CEC3

|

High Pressure Manifold - C.A.T. CONSTRUCTION

C.A.T. CONSTRUCTION HIGH PRESSURE MANIFOLD IS A TRAILER-MOUNTED FRACTURING UNIT DESIGNED FOR SETTING THE DIRECTION OF THE FLUID (ALSO PROPPANT LADEN) BETWEEN THE LOW-PRESSURE LINE (BLENDER - HIGH PRESSURE PUMP) AND HIGH-PRESSURE LINE (HIGH PRESSURE PUMP - WELL HEAD).

Description

C.A.T. Construction High Pressure Manifold was designed for maximum working pressure of 15 000 psi. The unit is equipped with thirty two 4’’ (Fig. 206, Hammer Lug type) low-pressure ports, fourteen 3’’ (Fig. 1502, Hammer Lug type) high-pressure input ports, and four 4’’ (Fig. 1502, Hammer Lug type) high-pressure output ports. The unit was designed for maximum rate of 128 bpm. There are 2 units.

|

Tech Specs Dimensions |

• Length: 11,80 |

|

Low pressure ports |

• Twelve 4’’ (Fig. 206, Hammer Lug type) low-pressure input ports |

|

High pressure ports |

• Fourteen 3’’ (Fig. 1502, Hammer Lug type) high-pressure input ports |

|

Flow capacity |

• Maximum rate: 128 bpm (~20,35 m3/min)

|

MT-132 HP Stewart & Stevenson Blender

The Stewart & Stevenson MT-132HP is a trailer-mounted 128 bbl/min fracturing blender designed to mix slurries for fracturing treatments and providing boost pressure.

Description

Blender MT-132 is capable of handling a wide array tasks associated with complex fracturing operations in harsh oilfield conditions. The unit is capable of operating in temperature ranges from -40oC to 46oC. Maximum proppant load is equal to 21 250 pounds per minute and maximum concentration is equal to 20 PPA (2 400 kg/m3). There are 3 units

|

Tech Specs Dimensions |

• Length: 14,00 m |

|

Front deck engine |

• Diesel’s Engine, Caterpillar Model C18 |

|

Rear deck engine |

• Diesel’s Engine, Caterpillar Model C18 |

|

Suction pump |

• Gorman-Rupp 12” x 12” |

|

Suction manifold |

• 3 X 8’’ Fig. 206 Hummer Lug connections |

|

Discharge pump |

• Mission Magnum 14” x 12” XP |

|

Discharge manifold |

• 12 X 4’’ Fig. 206 Hummer Lug connections |

|

Liquid chemical additive system |

• Five chemical injection systems each complete with Micromotion Coriolis flowmetres and transmitters |

|

Dry chemical additive system |

• Two variable-speed, hydraulically driven, stainless steel, dry additive feeders |

|

Tub |

• Constant fluid level in the tub can be kept automatically. |

|

Fluid’s measurement |

2 X Rosemount 8732 Magnetic Flowmeters – suction and discharge side |

|

Additional |

• Various possibilities for the direction of fluid flow:

|

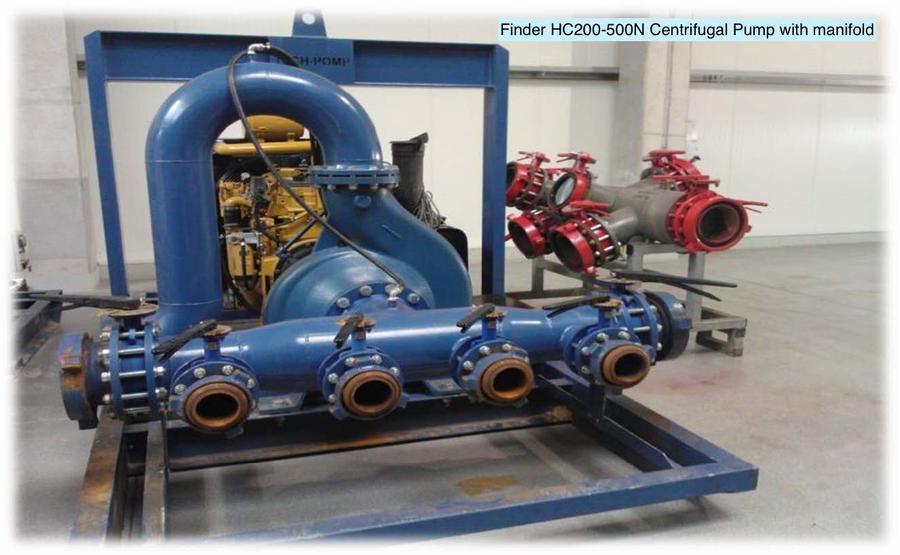

Liquid Additive System

C.A.T. Construction LAS trailer-mounted unit is used to pump liquid chemicals during hydraulic fracturing operations. The main task of the unit is to precisely add and measure the amount of liquid chemical additives in real time during the hydraulic fracturing job.

Description

LAS unit has an insulated compartment to house 10 tote chemical tanks for 2640 gallons of chemical storage capacity. All tanks are suitable to be loaded/unloaded by forklift, and all of them are equipped with level indicators and additional level control system with display on control panel in operator’s cabin. Four tanks are equipped with stainless steel mixers. LAS is equipped with ten chemical injection pump systems, two transfer pumps and one centrifugal pump. The chemical additive pumps are electrically driven and provide failure-free injection of chemical additives. The metering system includes Coriolis flowmeters enabling accurate measurement of each chemical liquid additive injected. The discharge of each pump is fitted with a 75’ (~23m) chemical hose. Additionally, the unit is equipped with a Gorman-Rupp centrifugal pump, capable of pumping at 40 bpm. There is 1 unit.

|

Tech Specs Dimensions |

• Length: 13,00 m |

|

Power Supply |

• Diesel’s Engine, John Deere model 4045HF120 |

|

Controlling |

• Automatically from the U-DAC (AccuFracTM module) |

|

Liquid Chemical System |

• The system contains the following pumps:

|

|

Cleaning chemical lines |

• After using each of pumps it can be necessary to clean it from chemicals. There are following methods: |

|

Centrifugal pump |

• Gorman – Rupp 6’’ X 6’’ |

|

Transfer pumps |

• Two progressive cavity pumps: |

|

Measurement system |

• Each IBC pallet has an electronic level indicator, coupled with operator’s cabin |

|

Additional |

• Arctic unit, capable of operating in temperature ranges from -30oC to 40oC

|

SK-2000 ACSEU Convey-All Sand Mover

Convey-All Sand Mover model SK-2000-ACSEU is a trailer-mounted unit designed to store and deliver proppant during hydraulic fracturing treatments.

Description

The unit is equipped with four compartments that allow to load 45,6 m3 of bulk material (equal to 80 tons of proppant). Each of the compartments has an inlet hatch located on the top of the unit and two 3’’ type FB connections. Complete unloading of each compartment is possible, thanks to remotely controlled hydraulic valves on the bottom of the unit. Proppant is moved in the direction of the blender by the belt conveyor which allows for transfer of the material at a speed of 40 000 lbs/min (18,1 tons/min). The Sand Mover is equipped with a scale. Readings are displayed on the unit and in the U-DAC. There are 8 units.

|

Tech Specs Dimensions |

• Length: 12,53 m Width: 2,53 m |

|

Deck engine |

• Diesel’s engine, Caterpillar model C4-4 |

|

Efficiency |

• The rate of bulk material transfer – 40 000 lbs/min (18,1 tons/min) |

|

Support system |

• Sand Mover has four independently controlled supports allowing for the safe placement on the ground. |

|

Weight’s measurement |

• The unit is equipped with a scale showing the contents of stored material with an accuracy of 50 kg |

|

Compartments |

• Sand Mover has four independently compartments

|

SK-3000 ACSEU Convey-All Sand Mover

Convey-All Sand Mover model SK-3000-ACSEU is a trailer-mounted unit designed to store and deliver proppant during hydraulic fracturing treatments.

Description

The unit is equipped with five compartments allow loading of 62,5 m3 of bulk material (equal to 100 tons of proppant). Each of the compartments has an inlet hatch located on the top of the unit and two 3’’ type FB connections. Complete unloading of each compartment is possible, thanks to remotely controlled hydraulic valves on the bottom of the unit. Proppant is moved in the direction of the blender by the belt conveyor which allows for transfer of the material at a speed of 40 000 lbs/min (18,1 tons/min). The Sand Mover is equipped with a scale. Readings are displayed on the unit and in the U-DAC. There are 2 units

|

Tech Specs Dimensions |

• Length: 15,85 m |

|

Deck engine |

• Diesel’s engine, model: Caterpillar model C4-4 |

|

Efficiency |

• The rate of bulk material transfer – 40 000 lbs/min (18,1 tons/min) |

|

Support system |

• Sand Mover has four independently controlled supports allowing for the safe placement on the ground. |

|

Weight’s measurement |

• The unit is equipped with a scale showing the contents of stored material with an accuracy of 50 kg |

|

Compartments |

• Sand Mover has five independently compartments

|

Unibelt-1800 Convey-All Belt Conveyor

Convey-All Belt Conveyor Model Unibelt-1800 is a trailer-mounted fracturing unit designed to deliver proppant from sand movers to blender.

Description

A single belt conveyor (Unibelt) is a unit which is used by United Oilfield Services in situation of multi-stages hydraulic fracturing. It happens when the amount of required proppant is greater than possibility of its storage in the SK-2000 or SK-3000 Sand Movers. Belt conveyor is powered by Caterpillar Diesel Engine Model C4-4 and allows to move the proppant at speeds up to 22 000 lbs/min (~10 tons/min).

|

Tech Specs Dimensions |

• Length: 16,00 m |

|

Engine |

• Diesel’s Engine, Caterpillar model C4-4, |

|

Efficiency |

• The rate of bulk material transfer – 22 000 lbs/min (10 tons/min) |

|

Support system |

• Single Belt Conveyor has four independently controlled supports allowing for the safe placement on the ground

|

Retention Tank

Retention Tank is a trailer-mounted, fully insulated unit having a space bounded by the chambers with variable overflow space to ensure longer time of linear gel hydration. The unit is used when it is necessary to hydrate a linear gel longer than it is possible in hydration unit. Retention tank is also used as a water tank.

Description

Retention tank belonging to United Oilfield Services is designed to extend the time of linear gel hydration. Given the fact that capacity of this unit is 73 m3 it allows for an extension time of hydration over than 4,5 min (with the rate of 100 bpm). During fracturing operations when the extension of hydration time is not necessary, this unit is used as a water tank. In the upper part of this tank there is a hatch enabling to fill smoothly from the source. Retention tank is equipped with 4’’ type Camlock connection with a TW adapter. It is possible to connect retention tank with other frac tanks with a manifold Fig. 100 type Hammer Lug connection. There is 1 unit.

|

Tech Specs Dimensions |

• Length: 12,14 m |

||||

|

Capacity |

• Capacity of each unit: 431,9 bbl (~73m3)

|

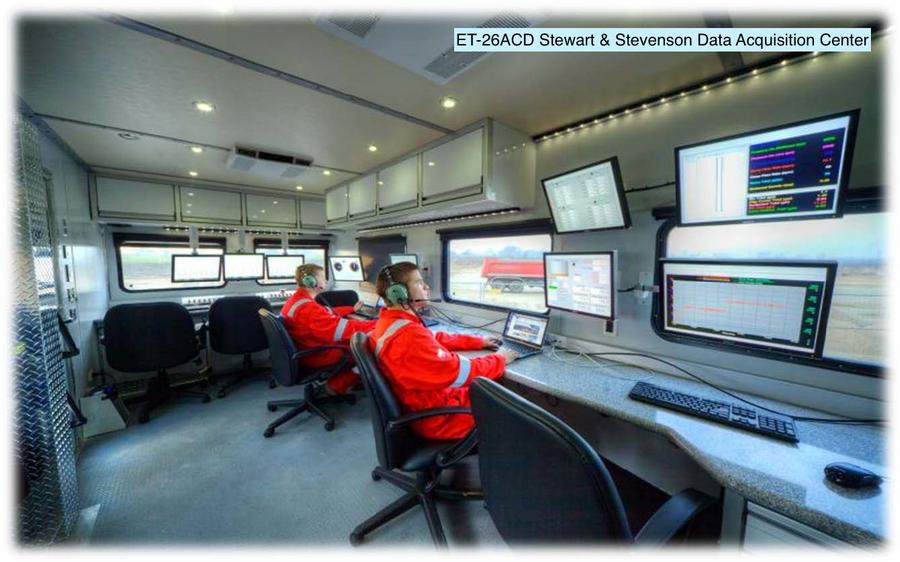

ET-26ACD Stewart & Stevenson Data Acquisition Center

The Steward & Stevenson Model ET-26ACD is a trailer-mounted control and data acquisition center capable of operating in harsh oilfield environments. The unit provides operators an environmentally controlled area to control and monitor well treatments.

Description

The unit is designed to operate fracturing pumps, blenders, the LAS unit, the Hydration unit, and acquire data in real-time. The computers have also been outfitted with software crucial to job design and frac analysis. Capable of operating in an ambient temperature range of -40oC to 46oC, and ability to be transported over non-grade road surfaces in the often rough environments found in the oilfield make this Data Van the keystone of the UOS Fracturing operation. UOS Fracturing offers remote data transmitting services via satellite. All fracturing jobs can be viewed in real time from any computer with an internet connection. The U-DAC will house the engineering station that will monitor and analyze all incoming job data. There are 2 units.

|

Tech Specs Dimensions |

• Length: 8,70 m

|

|

Power supply |

• U-DAC is powered by a 20 kW generator driven by diesel engine |

|

Software |

• AccuFracTM (data capture, blender, hydration unit, control of chemical additives) |

|

External electrical connections |

|

Acid Tank

Acid Tank is a fully insulated unit adapted to store and deliver the hydrochloric acid to the high-pressure pumps used in the acid treatment of the well before the hydraulic fracturing.

Description

Acid Tank is designed to store 40 m3 of liquid. The tank is fully resistant to hydrochloric acid (HCl). The unit is equipped with a centrifugal pump which is used for circulating acid and providing a boost pressure to high-pressure pump. The tank has also ability to circulate using the air system (barbotage system). Acid tank is equipped with 2’’ Camlock port and 4’’ Hammer Lug, type 206 ports allowing to connect IBC – pallet container and truck delivering the acid. There is 1 unit.

|

Tech Specs Dimensions |

• Length: 9,25 m |

|

Capacity |

• Capacity of unit: 40 m3

|

|

Connections |

• Fluid avoids the centrifugal pump: |

.jpg)