Solids Control Equipment - Package #2

No Longer Available

Email for more infoPriced to Sell @ Auction Values!!!

Can Mix & Match to meet your needs between the four packages.

MAKE AN OFFER

Call to Inspect and Buy Today!!!

Call NOW! (800) 952-1973

Listing Details

ASSET PACKAGE #1

SS 2000 CENTRIFUGES WITH STANDS

UI-03 - located in Odessa, Texas yard $209,940

UIP-221 – located in Odessa, Texas yard $209,940

USC-706 – located in Odessa, Texas yard $185,820

SS 1000 CENTRIFURES WITH STANDS

U85-136 – located in Odessa, Texas yard $142,560

USC-202 – located in Odessa, Texas yard $138,240

USC-203 – located in Odessa, Texas yard $142,560

40HP FEED PUMPS

FPUI-09 – located in Odessa, Texas yard $7,860

PM-705 – located in Odessa, Texas yard $7,860

PM-707 - located in Odessa, Texas yard $7,860

40HP VFD’S

VU40-101 – located in Odessa, Texas yard $10,380

VUI-218 – located in Odessa, Texas yard $10,380

120151820 – located in Odessa, Texas yard $10,380

20HP FEED PUMPS

122-P – located in Odessa, Texas yard $7,860

FPU828-16 – located in Odessa, Texas yard $7,860

FPU828-09 – located in OKC, OK yard $7,860

20HP CIRCULATING PUMPS

105-P – located in Celina, Texas yard $7,860

FPU-125 – located in Montrose, PA yard $7,860

PM-209 – located in Montrose, PA yard $7,860

20HP VFD’S

USC-201 – located in Odessa, Texas yard $10,380

USC-202 – located in Odessa, Texas yard $10,380

USC-206 – located in OKC, OK yard $10,380

VU20-101 – located in Montrose, PA yard $10,380

VU20-102 – located in Montrose, PA yard $10,380

LVU-107 – located in Montrose, PA yard $10,380

V-BOTTOM’S

DT20-01 – located in OKC, OK yard $12,720

DT20-02 – located in Dilley, Texas yard $12,720

DT20-03 – located in Montrose, PA yard $12,720

EZ LOAD TANK

UEL-102 – located in Celina, Texas yard $81,660

UEL-105 – located in Celina, Texas yard $86,880

UEL-106 – located in Celina, Texas yard $86,880

POLYMER INJECTION TANK

TBP-1200 – located in Celina, Texas yard $15,120

TBP-1300 – located in Celina, Texas yard $15,120

TBP-970 – located in Celina, Texas yard $14,040

TORPEDO TUBES

UTT-01 – located in OKC, OK yard $3,480

UTT-03 – located in OKC, OK yard $3,480

UTT-12 – located in OKC, OK yard $3,480

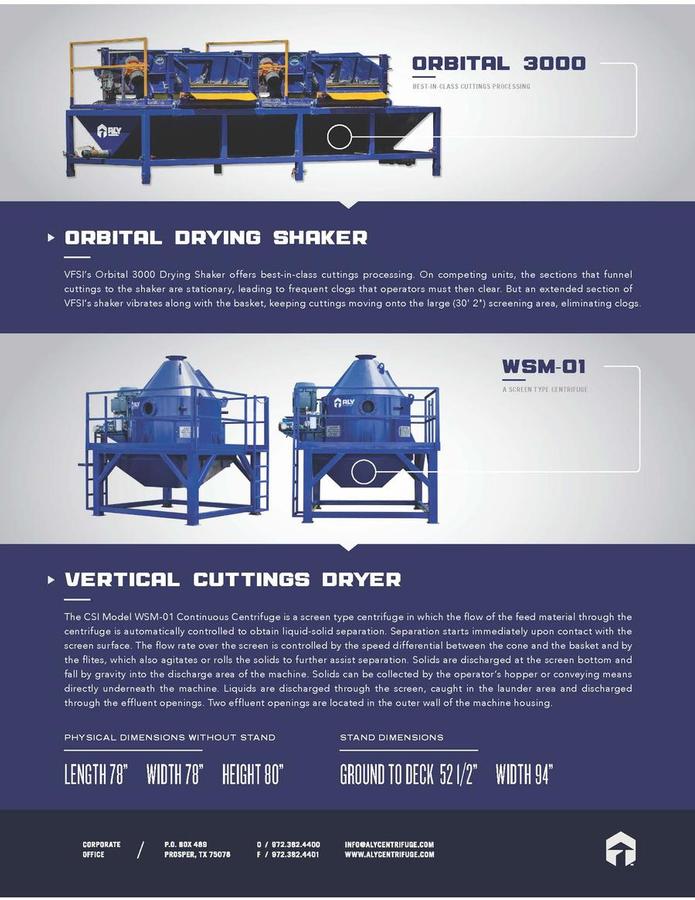

DRYING SHAKERS

USD-05 – located in Montrose, PA yard $16,200

USD-06 – located in Montrose, PA yard $16,200

USD-07 – located in Montrose, PA yard $16,200

USD-09 – located in Montrose, PA yard $16,200

USD-17 – located in Montrose, PA yard $16,200

USD-18 – located in Montrose, PA yard $16,200

Package Total - $1,637,820

Equipment Descriptions

SS 1000 Centrifuge

- Variable speed main drive

- Variable speed Gorman-Rupp pump

- 1000 LPM of un-weighted drilling fluid.

- The advantage of the Variable Speed “Smart Drive” is that it allows the pump to slow automatically if the load on the bowl increases, thus reducing the chance of overloading the centrifuge.

- High efficiency in removing fine solids

- Low operating costs and maintenance

SS2000 Centrifuge Features

- Variable speed main drive

- Variable speed Gorman-Rupp pump

- 2500 LPM of un-weighted drilling fluid.

- The advantage of the Variable Speed “Smart Drive” is that it allows the pump to slow automatically if the load on the bowl increases, thus reducing the chance of overloading the centrifuge.

- High efficiency in removing fine solids

- Low operating cost and maintenance

SS2000 Backdrive System

- Allows for complete variable speed main drive, pump drive and back drive for enhanced solids recovery

- All of the SS2000 Back Drives are equipped with the new XL10 LCD Touch Panel Screen.

- LCD Touch Panel screens allow for user friendly operation of the centrifuge unit.

Hydraulic Stand

The Hydraulic Centrifuge Stand addresses many of the safety concerns for contractors and provides a user friendly system to the rig personnel as well as cost savings to the customer.

Features Include:

- The use of a stairway versus a ladder, eliminates the use of a safety harness and fall protection equipment.

- Reduced trucking costs, all equipment is on a one compact load.

- Eliminates the use and cost of rig matting

- Eliminates the use and cost of a picker

- Eliminate safety hazards, some examples, tripping hazards, suspended loads.

Ez Load Hydra Lift System Features

- The E-Z Load Hydra-Lift System is a highly mobile, complete hydraulic dewatering system.

- With one load on a tri-axle trailer the unit can be taken to location, moved into position and be easily set up and running within minutes.

- The centrifuge(s) is raised and lowered by hydraulic rams enclosed in the legs of the main platform.

- When changing locations the E-Z Load Hydra-Lift System easily transforms hydraulically to the transport position and can be readily loaded without a picker.

Polymer Injection Tank

- Used for mixing and injection of polymer for clear water drilling and mud stripping. The two compartment design allows for hydration of polymer in one compartment while injecting to centrifuges from the opposite compartment.

- The pumping system is driven by an AC Variable Speed Drive, which allows for precise pump control thus reducing polymer waster.

- Each compartment holds 4m3.

Shale Tank

- Available in conventional straight wall or sloped wall design.

- Available in low or high sided shale tanks

- Sloped wall design will eliminate damage to wheel loader tires by centrifuge slides.

Pre Mix Processing Tank

- Premix/Process tanks range in size for 55m3 to 80m3.

- All premix/process tanks are a 3 compartment design complete with mix hopper, gun lines and agitators.

- Tanks can be used for premixing mud as well as clear water drilling.

Dewatering Tank Features

- The 60m3- Three compartment dewatering tank may be used for clear water drilling, mud stripping and displacing.

- Dewatering Tanks are equipped with a 4″ Gorman Rupp pump, used for fluid transfer and tank agitation thru gun system.

- A Variable Speed Drive is used instead of a conventional starter system to allow for pumping rate adjustment just by setting the desired rpm on the dial.

- The dewatering tank is capable of having the polymer injection tank mounted on top. This allows for less loads for transport from location to location. thus reducing trucking costs.

Underbalanced Processing

The underbalanced processing tank is versatile and may be used for many applications.

- The system may by used for displacement after surface holes, dewatering of surface mud, clear water drilling and the processing and transfer of underbalanced drilling fluids.

Rig Matting

Available In Sizes

8×20 Feet

8×30 Feet

8×40 Feet

Reinforced Lifting Slots

Email for more info