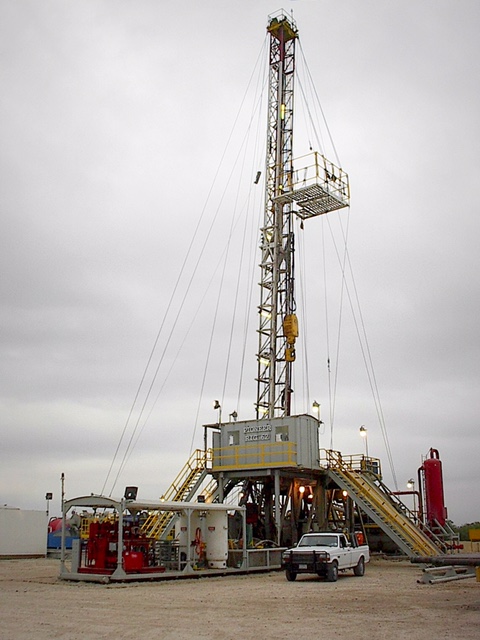

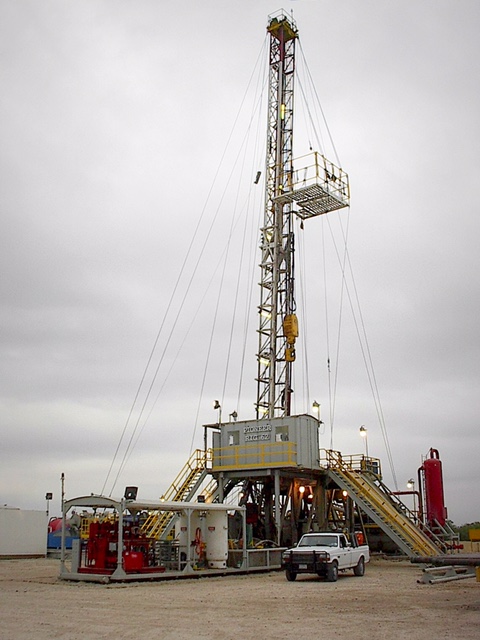

2008 HRI-1000E, 1,000HP TRAILER-MOUNTED ELECTRIC DRILLING RIG

No Longer Available

Email for more infoComplete w/SCR System, Top Drive, Skid System, & Iron Roughneck, (2) 1600HP Pumps

SELLER MOTIVATED TO SELL!

Reconditioned 2015

ORIGINAL COST OVER $15M IN 2008.

Click on photo for more details.

Listing Details

This is one of the most competitive 1000hp drilling rigs in the world. Cut drilling cost up to 40% over conventional rigs. Bid contracts while competitors can’t compete with your custom USA built portable top drive SCR 1600hp skid system drilling rig. All the bells and whistles.

Classification

1000 HP Trailer Electric

Drilling Depth Capacity

13,000’ w/5” drill pipe

Power System

Three (3) Cat. 3512C Diesel Engines with 3 Cat. 1225 KW AC Generators and IEC SCR I Drive, 4 Bays to power Draw works, Pumps, Lighting and Hotel Load, (2) 5120 Quincy air compressors

Draw Works

HRI 1000-E Single Drum with Wichita 3-25 KKB disk brake powered by two (2) GE 761 Traction motors w/ E-brake circulating cooling system

Mast

DSI 118’ with 425,000 # SHL

Drill Line

1-1/8” EEIPS

Substructure

DSI 17’ telescoping with 425,000 rotary capacity with a setback capacity of 300,000 # 15’ clear height from bottom of rotary to ground

Mud Pumps

Two (2) RS-F1600 HP pumps each powered by two (2) GE 752 Traction Motors

Top Drive

NOV TDS 10SA 250 Ton w/VFD house

Rotary

AB 27-1/2” with 53-1/4” center powered by GE 752 Traction motor

Block and Hook

250 Ton American Block strung up on 10 lines

Drill Pipe

12,000 5” 19.50 PPF Grade G-105

Drill Collars

Eighteen (18) 6-1/4” to 6-1/2” OD 4-1/2 x H conn

Four (4) 7-2/4” to 8” OD 6-5/8 API REG conn

Handling subs for 6-1/2 and 8” collars

Drill collar slips and wedding bands

All applicable change over subs bottom hole subs

Annular Preventer

Townsend Type 84

11” 5,000 psi WP

Ram Preventers

Townsend Type 82

11” 5,000 psi double ram

Choke Manifold

4” x 2” 5,000 psi WP

36” x 124” Gas buster

Accumulator System

Chiles (5) station 180 gal. (Electric over hydraulic with air pump backup system) w/remote control on rig floor with tubular handling equipment box on same skid)

Mud System

Two (2) Tank 750 BBL System

Two (2) King Cobra Hybrid 4 Panel Shakers

Derrick 2 cone desander powered by 6 x5 x 11 centrifugal

Derrick 16 cone desilter powered by 6 x 5 x11 centrifugal

Drilco style degasser

80 bbl. Trip Tank

Enclosed and elevated Mixing station

Two (2) 6 x5 x11 Centrifugal mixer pumps

Two (2) Agitators in shaker pits

Two (2) Agitators in suction pits

One (1) Agitator in slugging pit

Auxiliary Equipment

NOV-Iron Roughneck Type ST 80-C

Tool Pusher and crew quarters

210 KW Caterpillar generator powered by 3406 Caterpillar engine

One 300 BBL water tank/200 BBL Fuel Tank / Lube center combo

Automatic driller

Pipe spinner

OWI Electric over hyd. Survey machine

Forum 50’ Hydraulic Catwalk with 8000 # Capacity (remote operator station on floor)

Crew change house/ parts house combo

Skidding package to move up to 150’

Suitcases for all electrical, fuel, and water lines (also has enough for skid package)

Trolley system for BOP

Martin-Decker weight indicator

(4) Pipe tubs

Separate parts/tool house with washer and dryer

Wilson Tongs (breakout and makeup) air over hydraulic

One set 10’ 250 ton links (bails)

One 250 MGG 5-1/2 bottle neck elevators

Two 8000# Braden hydraulic hoist

3 sets Pipe racks